- Overview Features

- Included Items

- Tech Specs

Double Fan Enclosure Integrity Testing

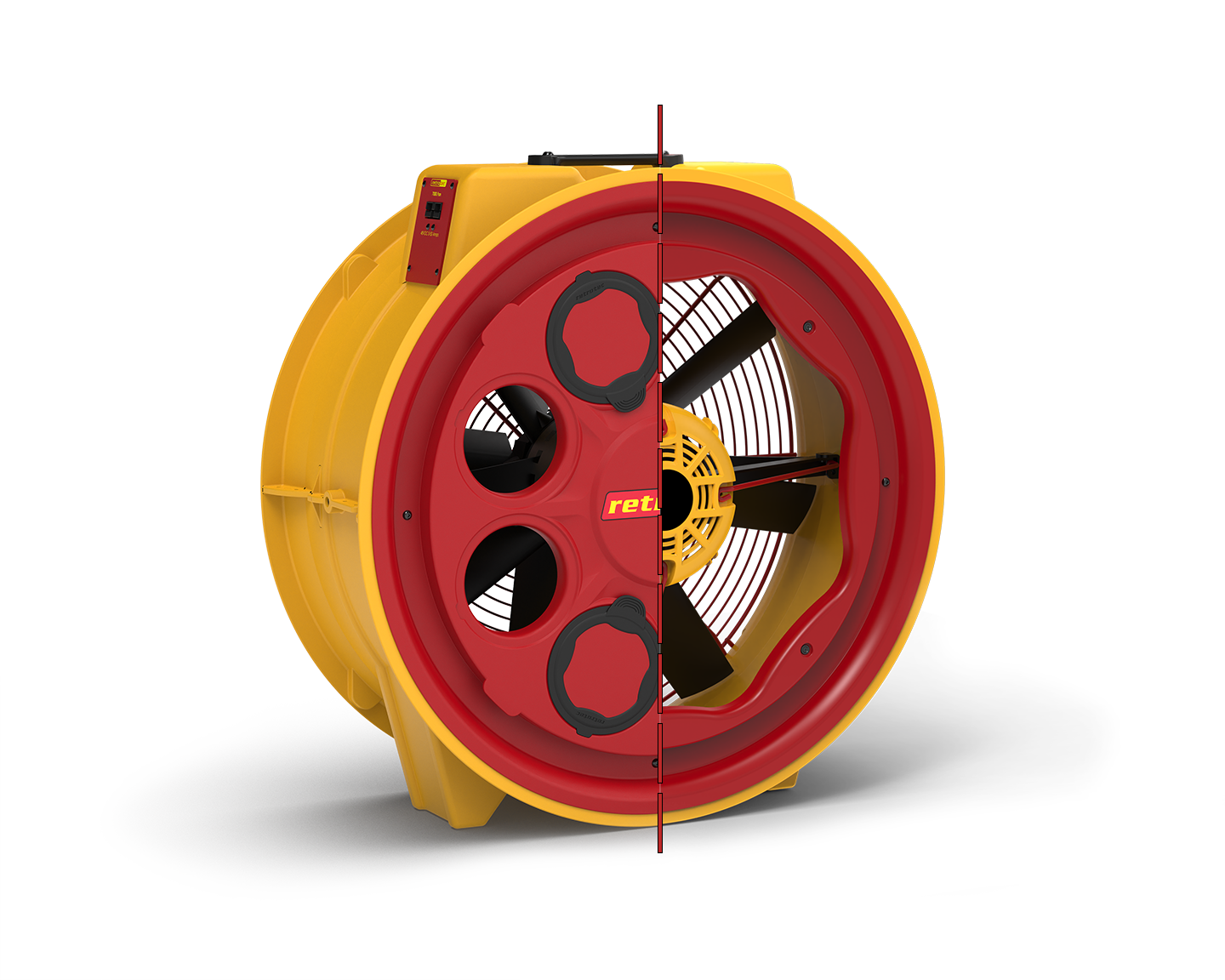

The Model 5210F Double Fan system features a large aluminum frame with a cloth panel, offering a powerful and flexible solution for enclosure integrity testing. This system consists of two complete 5110F systems that can be used independently or combined with the Leakage Split Kit for ceiling neutralization, making it highly adaptable for various testing scenarios.

Equipped with two 0.75 hp calibrated fans, the Model 5210F is ideal for large enclosures, handling up to 70,000 cubic feet (2,000 m³) for Inert agents and up to 140,000 cubic feet (4,000 m³) for halocarbon agents. The system also includes fan cases and tool cases for added convenience. Additionally, it features the newly released, industry-changing DM32X gauge, ensuring accurate and efficient testing.

Why Choose Retrotec for Enclosure Integrity Testing?

Retrotec pioneered the concept of Enclosure Integrity testing in 1984 and has remained the industry leader ever since. By promoting it within NFPA and authoring the first Enclosure Integrity standard in 1986, Retrotec set the foundation for modern testing methods. As the leading researcher in enclosure testing, Retrotec provides unparalleled expertise, with every major clean agent system manufacturer worldwide relying on its technology for hold time and peak pressure predictions. All Retrotec systems come with expert technical support, ensuring professionals have the guidance they need for accurate and efficient testing.

2 x 5000 Series Fan Set

- 5000 Series Calibrated Fan

(120V/60Hz, 240V/50Hz, or 110V/50Hz) - Range Ring A

- B8 Plate

- 8 x Blank Range Plugs

- Blower Door Tubing Kit

- Tubing Umbilical

- Fan Cover

- Power Cord

- System Calibration Verification Report

1 x Large Cloth Door Panel & Frame Package – Double Fan

- Double-Hole SmartCloth™ Wind Dampening Cloth Door

- Large SmartCloth™ Wind Dampening Cloth Door

- Large Aluminum Frame, Etched with Sizing Markings

- Traveling Case

1 x Leakage Split Kit

- Flex Duct

- Flex Duct Fill-In Sheet

- Subfloor test panel

- Field Calibration Plate for Modular Panel

- Flex Duct Case with Shoulder Strap

2 x DM32X Gauge Package

- DM32X Gauge

- Gauge Case

- USB-C Charging Cable

- Cat5 Cable

- ISO17025 calibration of DM32X

- Gauge Calibration Verification Report

2 x System Accessories Case

1 x Fan Case

8 x Roll of Grill Masks

| Model 5000 Fan | ||||

| Flow Into: | CFM | Litres/sec | M3/h | |

| Max Flow, per fan (60 Hz)

Reduces values by 15% for 50Hz fan |

Free Air | 6,400 | 3,020 | 10,874 |

| 50 Pa | 5,700 | 2,690 | 9,684 | |

| 75 Pa | 5,400 | 2,549 | 9,175 | |

| Minimum Flow: | ||||

| on Included Range B1 | 50 Pa | 111 | 52 | 188 |

| on Optional Range 74 | 50 Pa | 37 | 17 | 63 |

| on Optional Range 47 | 50 Pa | 21 | 10 | 35 |

| on Optional Range 29 | 50 Pa | 9 | 4 | 15 |

| Dimensions: | 22″ (55.9 cm) inlet diameter, 9.75″ (24.8 cm) long, 25″ (63.5 cm) height | |||

| Weight: | 33.5 lb (15.2 kg) or 35.2 lb (16.0 kg) with Ring A & Plated B8 installed | |||

| Flow Accuracy: | +/-5% | |||

| Power: | 120V@60hz/11A or 240V@50hz/4.9A or 110V@50Hz/ 8.9A | |||

| Recommended Fan Calibration Interval: | 5 years | |||

| Digital Gauge Model: | DM32X (Click Here) | |||

Request a Quote

Talk with a Sales Rep

Resellers, Testers, Trainers

Reviews

There are no reviews yet.